What is Utility Asset Management? 2026 Best Practices & Trends

The utility industry, as it exists today, manages some of the world's most complex and critical infrastructure.

From transmission towers spanning hundreds of miles to distribution networks serving millions of customers, utility companies oversee vast networks of physical assets that require systematic management, maintenance, and optimization.

But, as aging infrastructure meets growing demand and evolving technology, effective asset management has become essential.

A clear plan is imperative to mitigate the risks that result from failing infrastructure.

When a single component failure can cascade into widespread outages affecting thousands of customers, systematic asset management represents the difference between proactive control and costly reactive responses.

In this article, we’ll cover a comprehensive approach that enables utilities to make data-driven decisions about when to maintain, upgrade, or replace critical infrastructure while balancing cost efficiency with service reliability.

Table of Contents

→ Why is accurate, complete asset information essential for utilities?

→ What makes up a complete and reliable asset register?

→ How can utilities maintain asset register accuracy over time?

→ What does effective asset lifecycle management look like?

→ What organizational conditions enable successful asset management?

→ Which tools and technologies power modern utility asset management?

→ How do electric utilities manage assets in challenging environments?

→ What new trends and innovations are shaping asset management?

→ How is utility asset management evolving to meet the industry’s biggest challenges?

→ Ready to discover what your current inspections are missing?

What is utility asset management?

Utility asset management represents the systematic oversight of physical infrastructure across electric, gas, water, and telecommunications utilities. This discipline combines engineering principles, financial planning, and operational strategies to maximize asset value while minimizing risk throughout each component's operational lifecycle.

The scope of utility asset management extends across diverse asset categories, each with unique characteristics and requirements:

Electric utilities manage generation facilities, transmission lines, distribution networks, substations, and grid control systems.

Water utilities oversee treatment plants, distribution pipelines, pumping stations, and storage facilities.

Gas utilities maintain pipeline networks, compressor stations, and distribution systems.

Telecommunications providers manage fiber networks, cell towers, and switching equipment.

At Detect, we’re solely focused on the electrical grid, but all utility asset management focuses on aligning infrastructure decisions with broader operational goals.

Regulatory compliance, customer satisfaction, environmental stewardship, and financial performance are all core things to keep in mind. This strategic approach ensures that asset-related investments support long-term organizational objectives rather than simply addressing immediate maintenance needs.

Overview of utility asset management principles & practices

Effective utility asset management rests on several foundational principles that guide decision-making across the asset lifecycle. These principles provide the framework for systematic approaches that deliver consistent results regardless of asset type or operational environment.

A proper asset inventory forms the cornerstone of effective utility asset management. This includes a complete and accurate documenting every component's specifications, location, condition, and operational history. This enables informed decision-making by providing visibility into current asset status and historical performance patterns.

Lifecycle planning takes a long-term view of asset performance, considering total cost of ownership from acquisition through disposal. This approach optimizes investment timing by balancing immediate costs against future performance and replacement requirements. Utilities using lifecycle planning can extend asset useful life while avoiding premature replacements that waste capital resources.

Risk-based maintenance strategies prioritize resources based on asset criticality and failure probability rather than uniform scheduling. This approach recognizes that not all assets contribute equally to system reliability, enabling utilities to focus attention on components where failure would have the greatest operational impact.

Data-driven decision-making leverages historical performance data, predictive analytics, and real-time monitoring to inform maintenance and replacement decisions. An evidence-based approach replaces subjective judgment with objective analysis, improving both resource allocation and operational outcomes.

Performance monitoring and optimization establishes KPIs (key performance indicators) that track asset health, maintenance effectiveness, and operational efficiency. Regular performance reviews identify optimization opportunities while ensuring that asset management strategies continue delivering intended results.

Regulatory compliance integration ensures that asset management practices satisfy regulatory requirements while supporting operational objectives. This alignment prevents compliance issues while maximizing the business value of required investments.

Importance of asset management in the utility industry

In other industries, equipment failure primarily affects internal operations. Utilities, meanwhile, have a far wider range of effects, directly impacting community safety, economic activity, and quality of life.

Utility infrastructure represents enormous capital investments with operational lives measured in decades.

Transmission lines may operate for 50+ years, while generation facilities can function effectively for 30-40 years with proper maintenance. The scale of these investments demands careful management to protect capital value while ensuring reliable service delivery.

Service reliability expectations continue rising as communities become increasingly dependent on reliable services.

Similarly, business operations, healthcare systems, educational institutions, and residential customers all require consistent utility services to function effectively. Asset management directly supports these expectations by preventing unplanned outages and minimizing service disruptions.

Regulatory oversight adds another layer of complexity. Utility companies must demonstrate prudent practices to regulatory bodies while justifying rate structures and investment decisions. Systematic approaches to asset management provide the documentation and performance metrics necessary for regulatory compliance and rate case support.

Finally, economic efficiency becomes increasingly important as utilities face pressure to control costs while maintaining service quality. Effective oversight can reduce total lifecycle costs by optimizing maintenance timing, extending asset useful life, and avoiding premature replacements. These efficiencies translate directly into more affordable utility services for customers.

Operational challenges in the utilities industry

The utility industry faces unprecedented challenges that complicate the usual approaches to asset management. These evolving pressures require innovative solutions and adaptive strategies to maintain operational effectiveness.

Need for contactless monitoring and work solutions

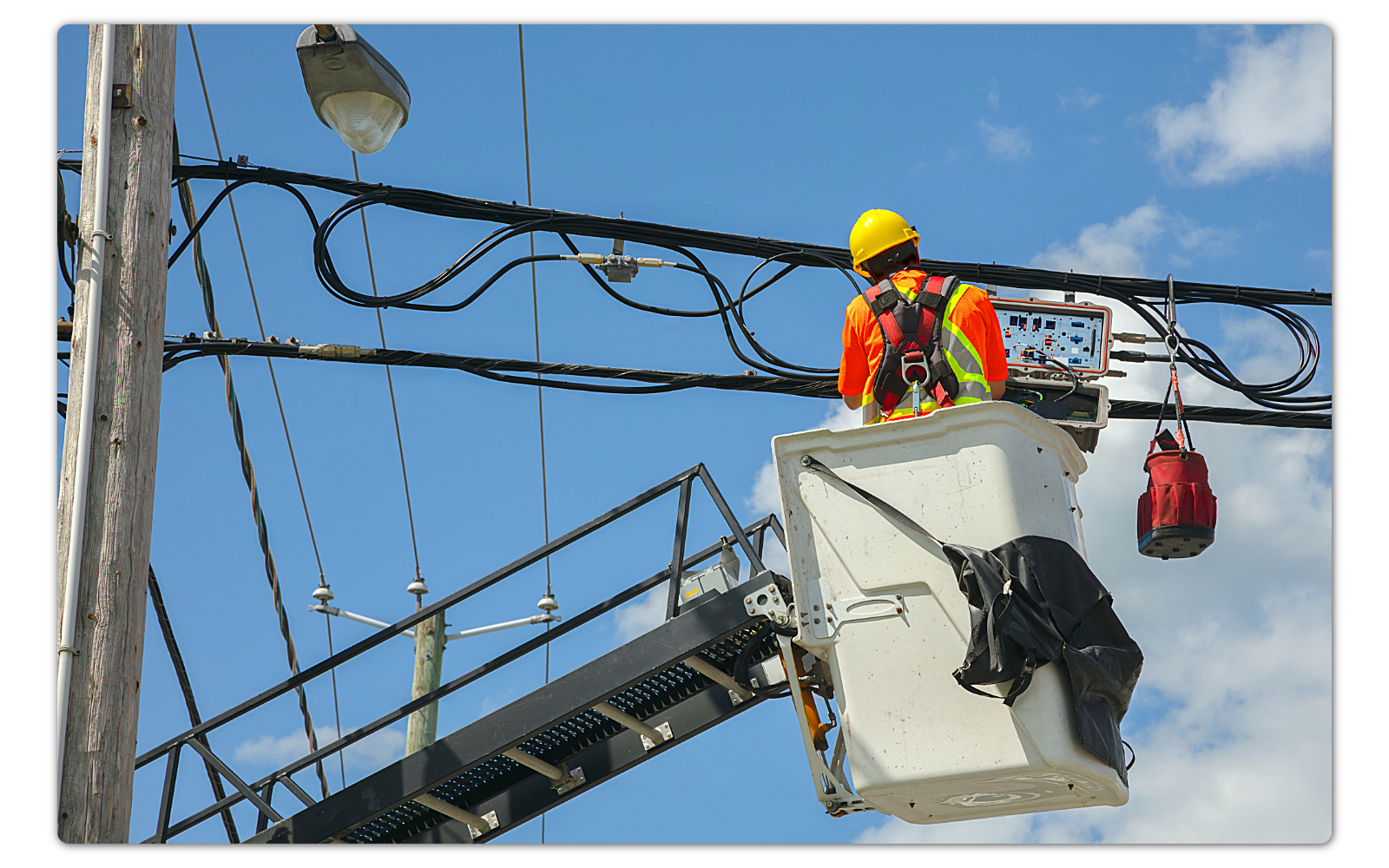

Physical access limitations increasingly constrain traditional inspection and maintenance approaches. Remote infrastructure, hazardous environments, and safety protocols often prevent comprehensive hands-on assessment of critical assets. Contactless monitoring technologies including drone inspections, satellite imagery, and IoT sensors enable utilities to maintain visibility into asset conditions without requiring physical presence.

Advanced imaging technologies can capture detailed visual data from transmission towers, pipelines, and other infrastructure that would be dangerous or expensive to access using traditional methods. These contactless approaches often provide more comprehensive coverage than human inspectors could achieve safely and economically.

Growing consumer expectations

Service reliability and transparency expectations continue rising as customers become accustomed to real-time information and immediate response in other aspects of their lives. Utilities must provide consistent service while keeping customers informed about planned maintenance, outage restoration, and system improvements.

Customer-facing technology platforms increasingly require integration with asset management systems to provide accurate service information and outage updates. This integration demands asset management systems that can support customer communications while maintaining operational effectiveness.

Movement on sustainability initiatives

Environmental compliance and sustainability goals increasingly influence asset management decisions. Utilities must integrate carbon reduction targets, renewable energy integration, and environmental impact considerations into asset planning and operations.

Sustainability initiatives often require significant infrastructure investments and operational changes. Asset management systems must support these transitions while maintaining service reliability and cost effectiveness. This includes managing the integration of distributed energy resources, energy storage systems, and smart grid technologies.

Growing labor shortage

Nearly 50% of the current utility workforce is expected to retire within the next decade, creating severe gaps in institutional knowledge and technical expertise. This workforce transition demands asset management approaches that capture and preserve critical knowledge while enabling less experienced workers to perform effectively.

Automation and digital workflows can help address labor shortages by streamlining routine tasks and providing decision support for complex activities. Asset management systems that integrate these capabilities help utilities maintain operational effectiveness despite workforce constraints.

Best practices for asset management in the utilities industry

Effective utility asset management requires implementing proven practices tailored to industry-specific operational and regulatory demands.

Standardize asset data collection across all departments and operational areas to ensure consistent, reliable information for decision-making. Standardized data collection eliminates information gaps and inconsistencies that can compromise asset management effectiveness. This includes establishing common naming conventions, data formats, and collection procedures that all personnel can follow consistently.

Prioritize maintenance by asset criticality rather than using uniform scheduling approaches. Asset criticality assessment considers each component's role in system reliability, replacement cost, and operational impact. A risk-based approach ensures that limited maintenance resources focus on assets where failure would have the greatest consequences.

Perform risk-based scenario analysis to evaluate potential failure modes and their operational impacts. Scenario analysis helps utilities prepare for various failure conditions while identifying vulnerabilities that require additional attention. This way utilities can develop contingency plans and allocate resources based on actual risk rather than subjective assessment.

Implement condition-based maintenance programs that use actual asset condition rather than time-based schedules to trigger maintenance activities. Condition-based programs optimize maintenance timing by performing work when it's actually needed rather than according to predetermined schedules that may be too early or too late.

Establish key performance indicators that track asset management effectiveness and support continuous improvement. KPIs should measure both leading indicators (like maintenance compliance) and lagging indicators (like outage frequency) to provide comprehensive performance visibility.

Developing utility inventory management strategies

Without accurate, complete asset information, utilities cannot make informed decisions about maintenance, replacement, or operational optimization.

Complete and accurate asset register development requires systematic cataloging of all infrastructure components, including technical specifications, installation dates, manufacturer information, and operational parameters. This baseline inventory establishes the foundation for all subsequent asset management activities.

Asset register accuracy demands ongoing maintenance to reflect system changes, additions, and retirements. Automated data collection systems can help maintain inventory accuracy by capturing changes as they occur rather than relying on periodic manual updates that may miss interim modifications.

Regular condition assessments can identify developing issues before they become critical while providing the performance data necessary for predictive maintenance programs.

Data quality control processes validate asset information accuracy and completeness. Quality control procedures should identify and correct data inconsistencies, missing information, and outdated records that could compromise decision-making effectiveness.

Finally, automated validation rules can identify obvious data errors like impossible dates or inconsistent specifications. However, human review remains necessary for more complex quality issues that require engineering judgment or operational knowledge to resolve.

Implementing asset lifecycle management

Asset lifecycle management takes a comprehensive view of infrastructure performance from initial planning through final disposal. This approach optimizes the total cost of ownership while maximizing asset value throughout its operational life.

Acquisition and installation best practices begin with careful planning that considers long-term operational requirements, compatibility with existing systems, and lifecycle cost implications. Proper planning prevents costly modifications and premature replacements that result from inadequate initial analysis.

Installation quality directly affects asset lifecycle performance. Proper installation procedures, quality control, and commissioning testing establish the foundation for reliable long-term operation. Documentation of installation details provides essential information for future maintenance and troubleshooting activities.

Proactive maintenance and upgrades extend asset useful life while maintaining operational reliability. Proactive maintenance programs use condition data and performance trends to optimize maintenance timing and scope. This approach prevents minor issues from developing into major failures while avoiding unnecessary maintenance that wastes resources.

Upgrade planning should consider technological advances, changing operational requirements, and lifecycle economics. Strategic upgrades can extend asset life while improving performance, but they require careful analysis to ensure positive return on investment.

Decommissioning and replacement planning ensures smooth transitions while maximizing value from retiring assets. Replacement timing should consider asset conditions, technological alternatives, and operational requirements. Early replacement wastes capital value, while delayed replacement risks reliability and increases maintenance costs.

These procedures should also address environmental requirements, salvage value recovery, and system reconfiguration needs. Proper planning minimizes service disruptions while ensuring compliance with regulatory requirements.

Conditions for successful asset management

Sustainable asset management success requires organizational capabilities and cultural elements that support long-term program effectiveness.

Leadership buy-in provides the organizational support and resource allocation necessary for comprehensive asset management implementation. Without leadership commitment, asset management programs often become fragmented efforts that fail to deliver intended benefits.

Staff training ensures that personnel have the knowledge and skills necessary to implement asset management procedures effectively. Training programs should address both technical skills and the organizational processes that support asset management objectives.

Centralized data systems provide the information infrastructure necessary for effective asset management. Centralized systems eliminate data silos while ensuring that all personnel have access to current, accurate asset information.

Utility asset management tools and technologies

Asset management today relies on sophisticated technologies that enhance visibility, improve decision-making, and optimize operational efficiency.

Geographic Information Systems (GIS)

Asset mapping and spatial analysis capabilities enable utilities to visualize infrastructure networks and analyze spatial relationships that affect operational planning. GIS systems provide the geographic context necessary for network analysis, outage management, and field operations coordination.

Spatial analysis identifies patterns and relationships that might not be apparent in traditional tabular data presentations. This capability supports predictive analysis, risk assessment, and resource optimization by considering geographic factors that influence asset performance.

Spatial data management and visualization

Digital twins and 3D modeling create virtual representations of physical infrastructure that support analysis and planning activities. Digital twins integrate real-time operational data with detailed asset models to provide comprehensive system visibility.

3D visualization enhances understanding of complex infrastructure relationships while supporting training and planning activities. These visual tools help personnel understand system configurations and operational impacts that might be difficult to grasp from traditional documentation.

Asset inventory and mapping

GPS tagging and RFID integration automate asset identification and location tracking. These technologies reduce manual data collection requirements while improving inventory accuracy and accessibility.

Automated identification systems support field operations by providing immediate access to asset information and maintenance history. This capability improves maintenance quality while reducing the time required for asset identification and documentation.

Network analysis and modeling

Outage prediction and network optimization capabilities use network models to simulate various operational scenarios and identify potential vulnerabilities. Network modeling supports contingency planning while identifying optimization opportunities that improve overall system performance.

Predictive modeling can identify assets whose failure would have the greatest system impact, enabling utilities to prioritize maintenance and replacement resources based on actual operational risk rather than subjective assessment.

Work order management and scheduling

Crew routing and productivity optimization considers asset locations, skill requirements, and travel time to maximize field crew effectiveness. Optimized scheduling reduces travel time while ensuring that crews have the necessary skills and materials for assigned work.

Mobile work order systems provide field crews with real-time access to asset information, work instructions, and documentation capabilities. This technology improves work quality while reducing the administrative burden associated with traditional paper-based systems.

Preventive and predictive maintenance

IoT-enabled monitoring provides continuous visibility into asset conditions and performance parameters. IoT sensors can monitor temperature, vibration, electrical parameters, and other indicators that reveal developing issues before they become critical.

Predictive maintenance systems analyze monitoring data to identify patterns that indicate impending failures. This capability enables utilities to schedule maintenance based on actual need rather than predetermined schedules, optimizing resource utilization while preventing unexpected failures.

Utility asset management software

Asset management software platforms provide comprehensive functionality that supports all aspects of utility asset management. These platforms integrate asset inventory, condition monitoring, maintenance planning, and performance analysis in unified systems that eliminate information silos.

Vendor comparison and features evaluation should consider functional capabilities, integration requirements, scalability, and total cost of ownership. Different vendors offer varying strengths in areas like mobile capability, predictive analytics, or industry-specific functionality.

Selection criteria should emphasize long-term strategic fit rather than initial cost considerations. Asset management systems represent long-term investments that affect operational effectiveness for many years, making strategic alignment more important than short-term cost savings.

Electric utility-specific asset management solutions

Electric utilities face unique challenges related to safety, reliability, and environmental conditions that require specialized asset management approaches.

Addressing harsh environments

Electric utility infrastructure often operates in challenging environmental conditions including extreme temperatures, corrosive atmospheres, and severe weather events. Asset management systems must account for these environmental factors when planning maintenance and predicting asset life.

Environmental monitoring helps utilities understand how local conditions affect asset performance and adjust maintenance strategies accordingly. This environmental awareness improves maintenance effectiveness while extending asset life in challenging conditions.

Real-time data connectivity

Electric grid operations require immediate response to changing conditions and developing issues. Real-time data connectivity enables utilities to monitor system conditions continuously while responding quickly to abnormal conditions or equipment failures.

Smart grid technologies provide the communication infrastructure necessary for real-time asset monitoring and control. These capabilities support both routine asset management and emergency response activities.

Field efficiency with rugged devices

Electric utility field operations often occur in challenging environments that require specialized equipment and devices. Rugged mobile devices ensure that field crews have reliable access to asset information and work management systems regardless of environmental conditions.

Mobile technology integration streamlines field operations by providing immediate access to asset data, work instructions, and documentation capabilities. This technology reduces administrative burden while improving work quality and safety compliance.

Cost savings through integration

Integrated asset management systems eliminate duplicate data entry and reduce administrative overhead associated with managing multiple disconnected systems. Integration also improves decision-making by providing comprehensive visibility into asset conditions and performance.

System integration ROI includes both direct cost savings from reduced administrative work and indirect benefits from improved decision-making and operational efficiency. These benefits often justify integration investments within relatively short payback periods.

Trends and innovations in utility asset management

Emerging technologies and changing industry requirements continue driving innovation in utility asset management approaches and capabilities.

Integration of smart grid and IoT

Real-time grid optimization capabilities use continuous monitoring and automated control to optimize system performance. Smart grid technologies enable utilities to respond automatically to changing conditions while maintaining optimal efficiency and reliability.

IoT sensor networks provide the data foundation for real-time optimization by monitoring asset conditions, environmental parameters, and operational performance. This comprehensive monitoring enables utilities to identify optimization opportunities that would be impossible to detect using traditional monitoring approaches.

Advanced analytics, AI, and machine learning

Automated insights for planning reduce the analytical burden on utility personnel while improving the consistency and accuracy of asset management decisions. AI systems can analyze vast amounts of data to identify patterns and relationships that support better planning and optimization.

Machine learning algorithms continuously improve their analytical capabilities by learning from operational outcomes and performance data. This continuous improvement ensures that AI-assisted decision-making becomes more valuable over time.

Sustainable and resilient practices

Aligning with ESG goals requires integration of environmental, social, and governance considerations into asset management decisions. Utilities must balance traditional operational objectives with sustainability goals and community impact considerations.

Resilience planning addresses climate change impacts, extreme weather events, and other threats that could affect infrastructure performance. Asset management systems must support resilience planning by modeling various threat scenarios and identifying vulnerabilities that require attention.

The new potential of utility asset management

The utility industry stands at a critical juncture where aging infrastructure meets unprecedented demand for reliability.

Traditional reactive maintenance approaches can no longer protect communities or budgets when 70% of transmission structures have exceeded their designed lifespan.

The technology exists today to transform asset management from reactive to predictive. The proven ROI is documented. The implementation frameworks are established.

The question isn't whether to adopt intelligent inspection systems—it's how quickly utilities can implement them before the next preventable failure occurs.

Ready to see what your current inspections are missing?

Discover the critical defects hiding in your network with a free audit of your assets. No strings, no obligations. Schedule your audit today.