Transmission Line Inspection for Failure Prevention and Grid Reliability

From Postmortem Analysis to Proactive Strategy

With over 70% of U.S. transmission infrastructure being more than 25 years old, failure isn’t a matter of if, but when.

Yet many utilities still rely on inspection methods that can't keep up.

When a single high-voltage transmission line goes down, it can cascade through the grid, sparking wildfires, halting industrial operations, and leaving entire communities in the dark. The stakes are highest not during the failure itself, but in the lead-up. There could be weeks, months, even years when early signs go unnoticed or unaddressed.

In this article, we’ll unpack real-world failure scenarios, examine why traditional inspection methods fall short, and outline a prevention strategy for utility operators facing increasing scrutiny and risk.

The hidden costs of transmission line failure

Transmission infrastructure might have been built for resilience 50 years ago, but it's aging fast.

As climate volatility intensifies and grid loads increase, these structures are being tested beyond their original limits. The failure of a single transmission line can cause cascading effects: localized blackouts, damaged equipment down the line, regulatory penalties, and loss of public trust. The costs quickly escalate beyond the immediate repair budget.

Consider the 2020 wildfire in Oregon’s Santiam Canyon.

An overloaded transmission line sagged into nearby vegetation during high winds, igniting a fire that destroyed thousands of structures and forced mass evacuations.

Utility investigations later found that the line in question had not been inspected in over a year and that vegetation clearance records were outdated. It’s a textbook example of how data blind spots, not just physical degradation, contribute to failure.

These aren’t isolated incidents. New grid demands continue to multiply. This includes AI data centers to electric vehicle expansion, each of which is layering additional stress on an already brittle system.

Every failure event triggers post-mortem analysis, but many utilities still lack the proactive tools to prevent the next one.

What the post-mortem tells us (but usually too late)

Post-failure investigations often reveal a frustrating truth: the signs were there.

Microcracks in cross-arms. Corrosion at the base of transmission towers. A loose bolt that was visible in drone footage but never reviewed. The data existed, but it wasn’t accessible, actionable, or timely enough to prevent the failure.

These stories surface a consistent pattern that there is a significant lag time between inspection and action. Traditional inspection workflows, whether ground-based, helicopter-driven, or third-party, often involve long processing windows. Image libraries sit untagged. Field teams hand off data with no clear routing path.

On top of that, the sheer volume of assets, including hundreds of miles of transmission lines, multiple types of transmission towers, makes prioritization a guessing game.

The postmortem gives us a timeline of what went wrong. But without a system that transforms raw inspection data into structured, real-time insights, it’s just a history lesson.

Why traditional transmission line inspections fail to scale

Conventional inspection programs were not designed for the velocity or volume of today’s grid environment. Ground teams are stretched thin, and helicopter flyovers are expensive, weather-dependent, and sometimes miss critical angles. Even with drones, image processing, and manual defect tagging often take weeks.

And scaling is all about consistency (not just coverage).

Different inspection crews interpret visual data differently. A hairline crack might be flagged by one team and dismissed by another.

The lack of standardized defect classification across asset types (lattice vs. monopole towers, AC vs. DC lines, etc.) introduces even more variability. This is a major liability, particularly when transmission tower inspection becomes a compliance requirement tied to NERC or FERC audits.

Then there’s the cost.

Transmission inspection costs vary widely by method, with ground patrols and helicopter inspections quickly ballooning in cost without guaranteeing defect detection. With utilities often managing thousands of line miles, even a 10% inefficiency balloons into millions in wasted spend annually.

The role of AI in transmission inspection analysis

The magic of Artificial intelligence lies in making patterns visible.

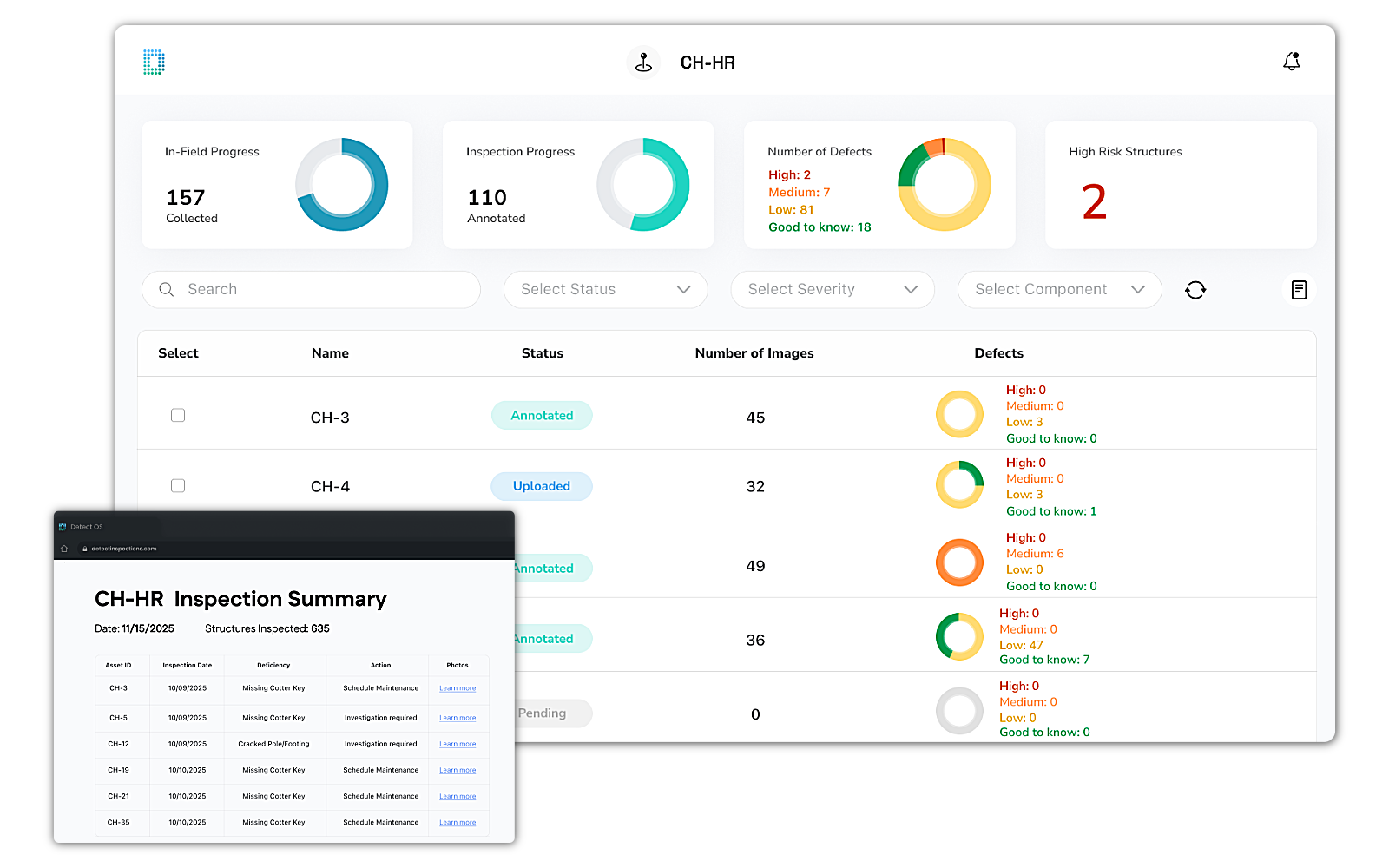

Platforms like DetectOS can review thousands of images from transmission line inspections in minutes, surfacing anomalies that would take human teams weeks to detect.

More importantly, they take those defects and contextualize them.

For instance, DetectOS can correlate a particular asset’s defect history with vegetation growth data, line loading trends, and prior inspection results. This allows utilities to not only flag a cracked insulator but to understand how environmental or structural stressors may accelerate its failure.

Inspection data analysis & action

Because the system is cloud-based and integrates with platforms like ArcGIS, SAP, and Maximo, inspection data doesn’t get trapped in a silo. Instead, it becomes an active signal within existing utility workflows, which means that:

Engineers can schedule crews in response to real-time alerts

Compliance teams can export inspection records aligned to regulatory schemas

Asset managers can view year-over-year defect trends at the portfolio level

In wildfire-prone regions, AI inspection also serves a public safety function.

Early detection of vegetation encroachment or downed equipment near energized lines can trigger mitigation actions long before red flag conditions escalate. As AI models continue to improve, they’ll even be able to predict defect likelihood—shifting utilities from a “fix it” mindset to a “prevent it” one.

Reframing overhead inspections: From line item to risk mitigation strategy

Historically, transmission inspection has been treated as a regulatory checkbox or fixed cost. You’ve got to account for this necessary but budget-constrained line item. That said, the economic equation changes when you factor in risk avoidance.

The cost of a major outage can reach millions per hour for industrial customers, and the reputational damage from wildfire liability can sink decades of goodwill.

Forward-thinking CFOs are beginning to ask a new question: What’s the ROI of not modernizing inspections?

AI-powered visual inspection platforms

AI-powered inspection platforms like DetectOS reframe inspections as a risk mitigation and operational efficiency strategy. By reducing the reliance on high-cost methods like helicopter flyovers, optimizing field team deployment, and helping prioritize critical maintenance actions, modern inspection platforms can lower total costs while increasing defect detection accuracy.

Additionally, as uptime becomes a commercial differentiator, especially in regions serving data centers, hospitals, and EV charging corridors, investments in faster, smarter inspections can directly support SLAs and regulatory compliance.

The shift is clear: by integrating AI inspection into a broader reliability strategy, transmission inspection becomes a profit protector and not just another O&M line item. And as regulatory expectations evolve, early adopters will be better positioned to demonstrate proactive compliance and infrastructure resilience.

Smart grid system: Inspection, integration, intelligence

Transmission line failure prevention comes from unifying the way utilities inspect, interpret, and act on asset data.

Inspections supported by AI technology are a starting point, but real changes happen when those insights flow seamlessly into the systems and teams that can operationalize them.

That’s why integration matters.

DetectOS’s native connections to GIS and ERP platforms ensure that inspection findings don’t stay buried in PDFs or proprietary databases. Every crack, hotspot, or vegetation risk becomes a live data point within a utility’s asset hierarchy that's visible to everyone from field ops to finance.

Continuous power utility asset intelligence

Intelligence, too, must be continuous.

Detect’s edge-to-cloud architecture allows for in-field data uploads, reducing lag time from inspection to insight. And with built-in feedback loops, the system learns from operator input over time, refining defect classification, prioritization rules, and risk scoring based on real-world outcomes.

The final piece is cultural. Preventing transmission line failure requires utilities to shift from reactive to anticipatory thinking and go from “What broke?” to “What’s next?”

That shift doesn’t happen overnight. But with the right tools and processes in place, it becomes not just possible, but inevitable.

Stronger grids start with smarter utility asset inspections

Detect exists to help utilities detect potential failures and stop them before they start.

With a software-first approach, field-tested AI, and native integrations across your asset stack, DetectOS empowers your team to scale inspections, reduce risk, and protect the grid at the speed modern life demands.

If you're ready to turn post-mortems into prevention, request a free audit or explore how DetectOS fits into your existing inspection and asset management workflows.

-

Transmission towers, also known as electricity pylons or overhead line towers, come in a variety of types classified by function, design, and support structure:

Functional categories (by role):

Suspension Towers: Carry conductors along straight paths or slight direction changes using suspension insulators.

Tension (Strain) Towers: Used where lines change direction or terminate, built to resist tension forces with strain insulators.

Terminal (Dead-End) Towers: Anchor endpoints of lines such as at substations or cable transitions, handling full conductor tension.

Transposition Towers: Employed to periodically switch conductor positions in multi-phase systems to balance electrical characteristis.

Structural/design categories:

Self-Supporting Towers: Free-standing, robust, and suitable for harsh terrain or heavy load capacities.

Guyed (Stayed) Towers: Use external guy wires for stability, cost-effective, often used where space or soil conditions limit self-supporting designs.

Lattice Towers: The most common high-voltage structures, made of steel frameworks that offer high strength-to-weight ratios.

Tubular Towers (Monopoles): Cylindrical steel or concrete poles with a compact footprint, often for urban or aesthetic-sensitive areas.

Hybrid Towers: Combine multiple design features—for example, lattice base with a tubular top—custom-built for terrain, load, or visual needs.

Circuit-based types: Classified by number of circuits—single, double, or multi-circuit towers.

Special variants: Region-specific or design-specific types—such as A/B/C/D-type towers (based on load and conditions), H-frame towers, or architecturally unique structures.

-

Inspection frequency is governed by regulatory standards and best practices to maintain grid safety:

Annual inspections are a common mandate, especially for vegetation management: NERC’s FAC-003 standards require annual inspections of vegetation conditions that could lead to flashovers.

Regulatory requirement: Transmission owners are required to inspect 100% of applicable transmission lines at least once per year, with no more than an 18-month interval between inspections on the same right-of-way.

Operational best practices: Some utilities perform biannual foot or climbing patrols for more immediate asset condition assessments.

So, a typical schedule includes:

Formal inspections: Annually (and at least once every 18 months).

Supplemental patrols: Twice a year or more, depending on risk factors like terrain, wind, or wildfire exposure.

-

Failures arise from a mix of environmental, mechanical, electrical, and operational factors:

Environmental stressors:

Lightning, fire, pollution, high winds (like typhoons), fog, ice buildup, and flashover all contribute to transmission line faults.

Conductor galloping due to ice loading and wind can cause mechanical vibrations, fatigue, or clearance problems.

Electrical and mechanical defects:

Faults commonly stem from joint failures, broken overhead cables, phase failures, or melting components like fuses.

Electrical treeing can degrade solid insulation over time, leading to discharge and eventual failure—particularly in underground systems.

External hazards:

Wildlife (birds), vandalism, and theft can damage conductors or insulators, triggering faults or failures.

Complex phenomena:

Unenergized (“idle”) transmission lines can become hazardous when induced by nearby active lines, especially during high-wind surges—suspected in events like California’s Eaton Fire.

Extreme weather events:

Tower collapses due to storms or extreme weather (as seen in Victoria, Australia) underscore the importance of structural resilience—even when maintenance records show no prior defects.