Early-Life HVDC Transmission Line Inspection Prevents $1M+ Outage

Project Details

New HVDC Renewable Intertie Carries Power Over 250mi

Confidential North American HVDC Renewable Intertie. A newly constructed high-voltage direct current (HVDC) transmission intertie exporting renewable generation to the broader regional grid.

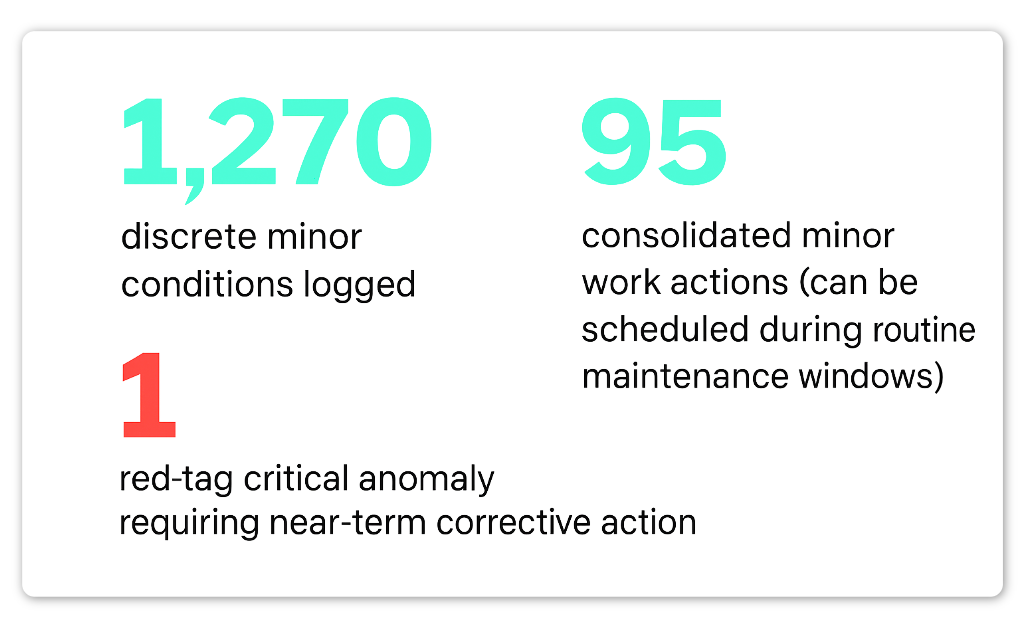

Results snapshot:

Conditions Flagged

>1,200 minor conditions triaged; 95 prioritized minor work actions created; 1 critical anomaly escalated for immediate intervention.

Avoided Impact

Week‑plus forced outage averted; >$1M protected revenue (energy + congestion/market effects) excluding emergency mobilization costs.

Safety & Sustainability

Eliminated extensive foot patrols and reduced helicopter flight hours; lower exposure, lower emissions.

The electric grid could aptly be described as the world’s largest machine. After all, this is a continent-spanning organism whose health depends on the fitness of millions of tiny components.

In one windswept corner of North America, that machine jumps cold ocean water to link two rugged coasts and move gigawatts of clean power inland. The intertie is young, state‑of‑the‑art, and mission‑critical. New steel, new insulators, new marine cables.

What could go wrong? Plenty. Especially if no one is looking too closely, due to the age of the structure.

The Challenge: New Doesn't Mean Risk-Free

New HVDC Assets Still Carry Early-Stage Structural Risk

When this major North American utility energized their state-of-the-art HVDC renewable transmission line, conventional wisdom suggested minimal risk. After all, this was brand-new infrastructure: fresh steel towers, pristine insulators, cutting-edge marine cables spanning 250 miles and 2,600 structures.

Fortunately, this utility's risk management team knew better. New doesn’t mean risk-free.

When it comes to new transmission assets, commissioning marks the beginning of real operating risk, not the end. In those critical first seasons, bolts relax, hardware settles through freeze-thaw cycles, and construction QA gaps surface as components mature into potential failure points.

For an HVDC backbone carrying gigawatts of renewable power, even a single structural failure could trigger cascading outages across the regional grid.

Helicopter patrols lack coverage speed for newly built corridors

Despite awareness of this hidden risk, there was another problem. Traditional patrol methods couldn't deliver comprehensive structural coverage fast enough or cost-effectively enough for what appeared to be "low-risk" new construction.

The Solution: AI-Powered Asset Visibility

Full-Corridor HVDC Inspection with AI-Driven Triage

The utility chose to deploy DetectOS, combining high-endurance drone capture with AI-assisted analysis to inspect every fastener, fitting, and conductor attachment across the entire corridor.

Campaign specifications

Duration

30 consecutive summer days

Coverage

100% of structures (2,600 lattice towers)

Data capture

122,714 geo-referenced images (1.05 TB)

Team

3 cross-trained operators

Processing

Real-time AI triage with same-day emergency flagging

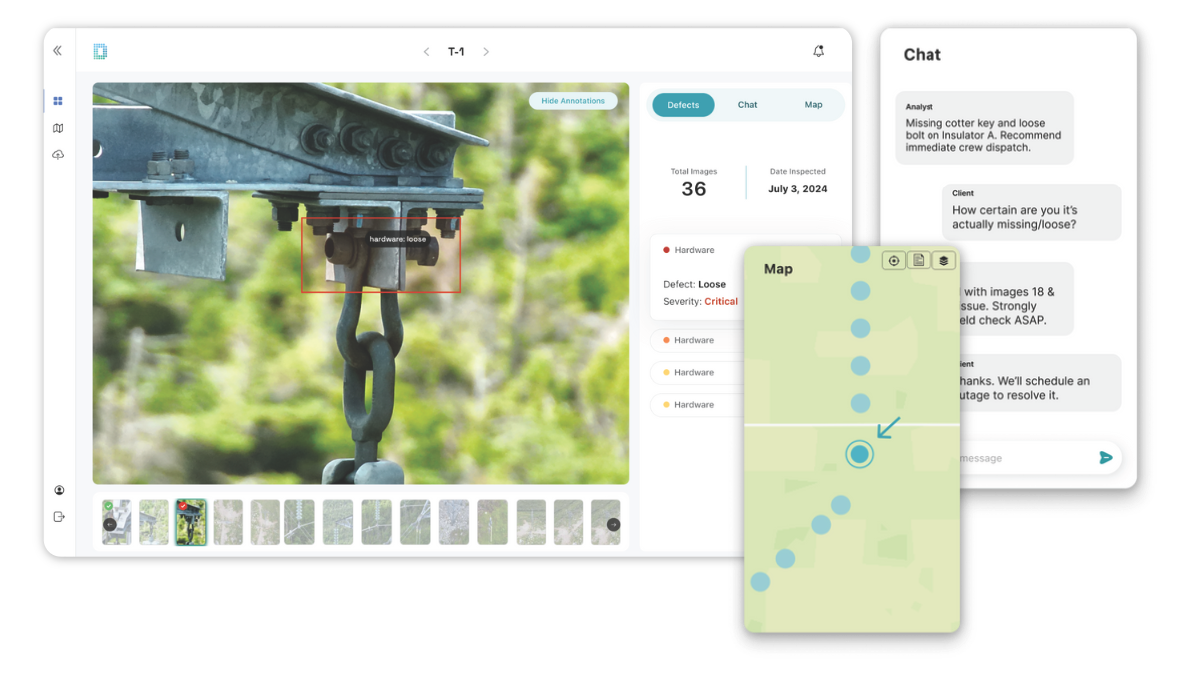

All raw imagery streamed into DetectOS throughout the days. Then, AI‑assisted triage accelerated analyst throughput so risks surfaced within hours—not weeks—of capture.

One Discovery Changed Everything

Loose Clevis Bolt Identified Before Catastrophic Failure

High in a suspension assembly supporting an HVDC conductor span, imagery flagged an irregular silhouette: the head and threads of a clevis bolt were visibly backed off, and the retaining cotter key was absent.

Subsequent zoom review confirmed severe loosening with only a few threads of engagement remaining. Under wind‑induced gallop or ice shedding, the remaining engagement could have failed, dropping the hardware load to adjacent components and risking a conductor drop.

Because the line is HVDC, a trip on this pole would strip a major renewable feed and could propagate protection actions upstream. The customer indicated that, if the defect were to occur under load, it could force an unplanned outage lasting more than a week, once site access, crane mobilization, and re-energization were considered.

Revenue exposure exceeded $1M, not counting emergency crew premiums, replacement hardware logistics, or penalties.

Drone data enables a 120-min targeted maintenance response

Armed with geolocated imagery and severity scoring, the operator was able to:

Schedule a brief planned outage on the affected structure’s span rather than endure a forced trip.

Dispatch one qualified climbing crew with the exact replacement cotter and torque specs in hand.

Bundle adjacent minor tasks (insulator hardware check, marker ball inspection) into the same window, maximizing the outage bite.

Technicians confirmed the bolt was indeed under‑torqued and without its cotter. They re‑seated, torqued to spec, installed a new cotter, and cleared the red tag.

Results: System-Wide Intelligence

Risk-Based Work Plans Replace Guesswork & Helicopter Flights

While the loose bolt grab headlines, the comprehensive inspection delivered broader operational intelligence:

Benefits: fewer truck rolls, more precision, less emissions

Safety: Eliminated hundreds of helicopter flight hours and foot patrols

Efficiency: Data-driven work packaging reduced truck rolls and repeat climbs

Sustainability: Drone-based approach significantly lowered carbon footprint

Precision: Exact part staging eliminated guesswork and return visits

Results: outages prevented, revenue protected

Detect’s 6-step framework to audit new transmission lines

The playbook the Detect team rolled out works for any transmission owner managing new or recently upgraded infrastructure where latent construction issues hide in plain sight.

Early-Life Baseline Scan

Capture 100% of new structures post-energization

AI-Assisted Risk Ranking

Let DetectOS auto-classify and prioritize anomalies

Smart Work Packaging

Convert findings into executable tasks with precise resource planning

Strategic Outage Alignment

Bundle high-severity fixes with planned maintenance windows

Remediation Audit

Capture post-repair imagery to confirm each issue was resolved and documented properly

Constructor Feedback Loop

Use evidence to close warranties and refine future construction specs

DetectOS

Audit New HVDC Lines Before the First Outage Costs You Millions

While one critical defect drew attention, the broader campaign delivered system-wide value. Every anomaly was geo-tagged, prioritized, and linked to actionable work plans, allowing the utility to move from uncertainty to precision.

Detect’s approach doesn’t stop at identification. After each fix, follow-up capture confirms the work was completed to spec, closing the loop with auditable proof and eliminating guesswork. This creates a living asset record that supports warranty enforcement, proactive maintenance, and smarter outage planning.

Whether you're commissioning new HVDC infrastructure or maintaining aging lines, Detect makes full-line audits fast, precise, and repeatable. Our no-cost audit offer puts this same inspection framework to work on your assets—complete with drone or mobile capture, AI-driven defect detection, expert validation, and a visual action plan you can take straight to your ops team.